Some means of measuring off distances accurately was required, similar to that which I used in my day job in industry via the use of the Apron handwheel dial, this I thought ought to be possible.

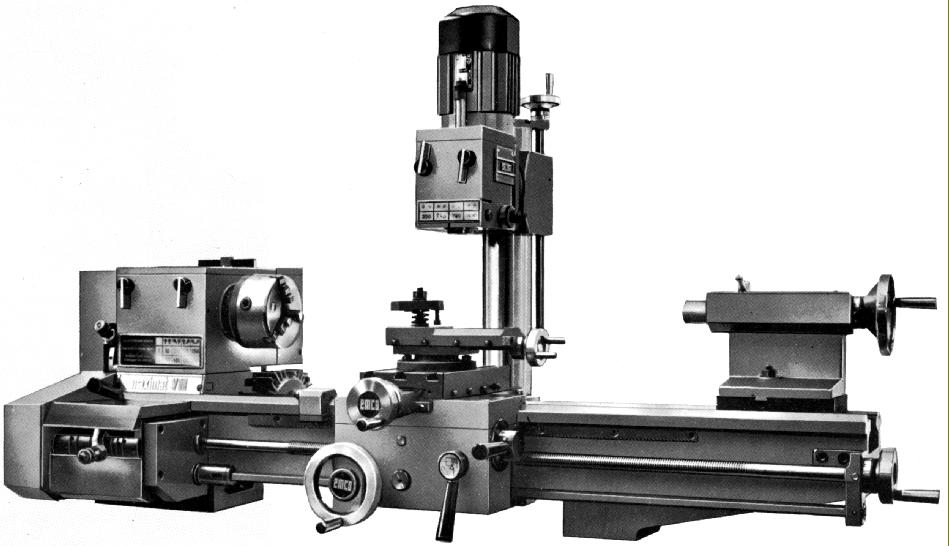

It is a bit like reading the old vernier scales of the pre-digital calipers, the measurement to a degree is open to interpretation, especially if the vernier is between lines. Measurements beyond this relied on the use of a good rule and my eyesight, which I have never considered good and it is after all just a comparator. This was only added when the milling facilities were added, which if I remember correctly was first started with a vertical slide and later followed by the adaptation of the Compact 5 milling and drilling unit at the back of the lathe bed.Īccurate measurements were, therefore, restricted to the use of the topslide, provided they fell within the range of the topslide movement. When the Compact 8 first appeared it had no longitudinal or leadscrew dial. Measuring the length of a workpiece on the Unimat lathes was never a problem as the longitudinal feedscrew was always engaged. Given my already largely Emco workshop it will come as no surprise to the reader that the next lathe I decided to purchase was a new Compact 8, this was not the very first machines which had chrome finished handwheels. Over the years our expectations grow and so do the size of the models we would like to build, it was soon realised that a larger lathe was needed.

This served me well for a number of years and when the Unimat 3 was introduced this too was added to the budding workshop. My first lathe after starting my apprenticeship was an Emco Unimat SL, purchased via a mail order catalogue.

0 kommentar(er)

0 kommentar(er)